Professional OEM Service

- Demand Understanding, Confirming and Analysis from Customer:

You can advise the specification that you need, or product information for our R&D department to verify.- Design:

After specification of product confirming, our R&D staff will start to design. We will concern the performance of features, appearance and the cost or what you are notice.- Trial Produce:

Design phase is completed. In order to ensure that the specifications meet the customer’s needs and the feasibility of the production, we will do trail product and evaluate produce process.- Examining:

Professional quality control with precision test equipment will stabilize the production capacity in the future.- Quality control:

Strictly quality control for mass production can eliminate rework of defective products and avoid the extra cost occurring. - Design:

Approximately 30 years in the business, TCC certainly knows how to manufacture RF products. We love what we do, and can help you realize your strategic objectives. TCC knows how to make your needs come true - and will deliver it to you under your own badge.

Based here in Taiwan, we have access to professionals who are both highly skilled and well experienced. We have the production flexibility and logistical support not available in other so-called "low cost" destinations or from "EMS" type services. We are the specialists in RF and are the people behind many of the big industry names - all of whom benefit from the environment of rigorous quality control and tight intellectual property enforcement that TCC offers.?

Contact us in confidence at sales@tcc-corp.com and let us know what you have in mind - let’s see how TCC can help.?

RoHS Compliance TCC is aggressively pursing a strict, formal company-wide action plans that will deliver compliance with RoHS. We are working closely with our suppliers to ensure that customers who require RoHS compliant products will be able to be ready before July 1, 2006.

Professional R&D Team TCC has about 10 persons whom have cornucopian RF developing experience in R&D team.? The professions include mechanical, RF and electronic design. Most of them have average 5-13 years experience in this field.

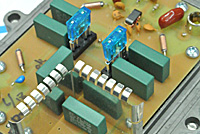

Professional Supplementary Instruments and Software TCC has some professional supplementary instruments and software to help our engineers developing products efficiently. They are PCB Prototype Machine, Modular Impluse Generator, Agilent Network Analyzer/Spectrum, Signal Generator, Surge Generator, Salt Spray Machine and ADS Layout/RF Simulation software. We can meet customes’ various demands flexibly and assist our customers to enter their target markets very soon.?

Patents TCC has several patents such as wound core splitter design, 360 degree centre contact seizure and state-of-the-art power isolation design on isolators. Not only it reduces lots of cost, but it also dilates gapes with competitors and improves TCC’s brand and competitiveness.?

ERP(Enterprise Resource Planning) System To upgrade customer service, TCC deploys its ERP (Enterprise Resource Planning) computerized management system for the new millennium in 2000. It helps TCC to integrate all organization’s operations (such as stocks/cost/sales order/shipping, etc.) efficiently and try to gain most benefits for our customers. ?

ISO 9001:2015 Certification We got ISO 9001:2015 certification. All TCC Quality Management Systems are fully compliant. Full certification details together with Assessment Schedule are available on request.?

Manufacturing Equipments and Processes The production quality control is to AQL Standards (MIL-STD-105E) IQC-IPQC-FQC. All units are tested for performance to electrical specification (Analyser Limited Line Controlled), SPC Torque Controlled, Automatic Machine, Leak tested and tested for Signal Continuity prior to packaging.